Electro-Pneumatic Positioner YT-1000R YT-1000R+SPTM, Angular stroke

Ordering code

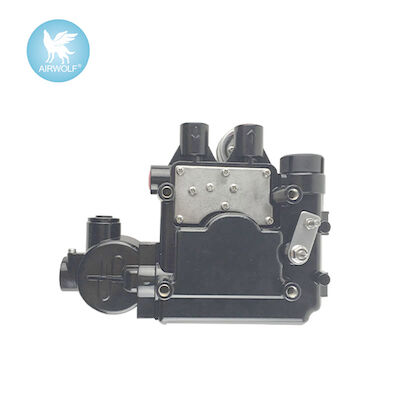

Description

The Electro-Pneumatic Positioner YT-1000R is used for operation of pnuematic rotary valve actuators by

means of electricalcontroller or control system with an analog output signal of DC 4 to 20mA or split ranges.

Demension

Specifications

| ltem . Type |

Single |

Double |

| Input Signal |

4-20mA DC |

| Impedance |

250 ± 15 Ω |

| Supply Pressure |

0.14~0.7MPa(1.4~7 bar) |

| Stroke |

0~ 90° |

| Air Connection |

PT(NPT) 1/4 |

| Gauge Connection |

PT(NPT) 1/8 |

| Conduit |

G(PF,NPT)1/2, M20 |

| Explosion Proof |

Ex dmb IlB T5 (KTL) |

| Ex dmb IlC T5 (KTL) |

| Ex ia IlB T6 (KTL) |

| Ex ia IlC T6 (NEPSI) |

| Ex dmb IIC T5/T6 (NEPSI) |

| Enclosure |

IP66 |

| Ambient Temp. |

Operating: -20℃~70℃(-4~158℉) |

| Explosion: -20℃~60℃(-4~140℉) |

| Linearity |

± 1% F.S. |

± 2% F.S. |

| Hysteresis |

± 1% F.S. |

| Sensitivity |

± 0.2% F.S. |

± 0.5% F.S. |

| Repeatability |

± 0.5% F.S. |

| Air Consumption |

2.5LPM (sup=0.14MPa) |

| Flow Capacity |

80LPM (sup=0.14MPa) |

| Material |

Aluminum Diecasting |

| Weight |

2.8kg (6.2 Ib) |

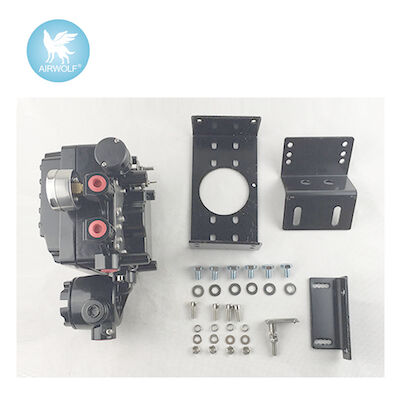

Installation Steps

(1) Proper bracket must be made in order to attach positioner on the actuator yoke.

Please consider following when making a bracket.

① Feedback lever should be leveled at 50% of valve stroke. (Refer to Step 7)

② Feedback lever connection bar of actuator clamp should be installed at the position that the valve

stroke and numbers which indicated on the feedback lever must be fitted. (Refer to Step 8)

(2) Attach YT-1000L to the bracket, which was produced in earlier step, by using bolts. Please refer to backside of the product

for size of bolts. The standard size of bolt is M8 X 1.25P, and other bolt sizes are available. Please contact YTC sales department.

(3) Attach YT-1000L (with bracket) to the actuator yoke - DO NOT TIGHTEN COMPLETELY.

(4) Connect YT-1000L feedback lever to the actuator clamp. The gap on the YT-1000L feedback

lever is 6.5mm. The connection bar thickness should be less than 6.3mm.

(5) Connect air filter regulator to the actuator temporarily. Set supply pressure of the regulator in order to position the actuator clamp at 50% of valve stroke

(6) Insert connection bar into the YT-1000L feedback lever. The connection bar should be inserted at the 50% point on the feedback lever, which would help to reduce hysteresis.

(7) If connection bar does not point at 50% point, then adjust bracket or feedback link bar position. Failure to position at 50% would lower the linearity of the positioner.

(8) Check valve stroke. The stroke numbers are indicated on the feedback lever. Position

connection bar at the number on the feedback lever according to the valve stroke. To adjust, move the bracket or connection bar.

Quality Standards

The company for the products are brand new original products, no second-hand and refurbished products, or leave a compensable ten and return the full amount, but the buyer due to our purchase of model error is not responsible for returns, another of the company's sales of products enjoy one year from the date of shipment quality assurance, according to the original quality standards, during warranty with product problems, need confirmation testing by the manufacturer, the supplier to be solved, the demand side due to storage, use, poor maintenance caused by lower-quality product, and not raise objections.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!